Exploring the Global Gearbox Manufacturing Landscape

As you explore the global gearbox manufacturing landscape, you’ll notice a complex interplay between traditional practices and cutting-edge innovations. Major players like Siemens and ABB are reshaping the industry, focusing on efficiency and sustainability. Meanwhile, emerging trends such as smart technology integration and additive manufacturing are pushing the boundaries of what’s possible. However, regional market variations present unique challenges and opportunities that demand careful navigation. What strategies are manufacturers adopting to stay ahead in this competitive environment?

Overview of Gearbox Manufacturing

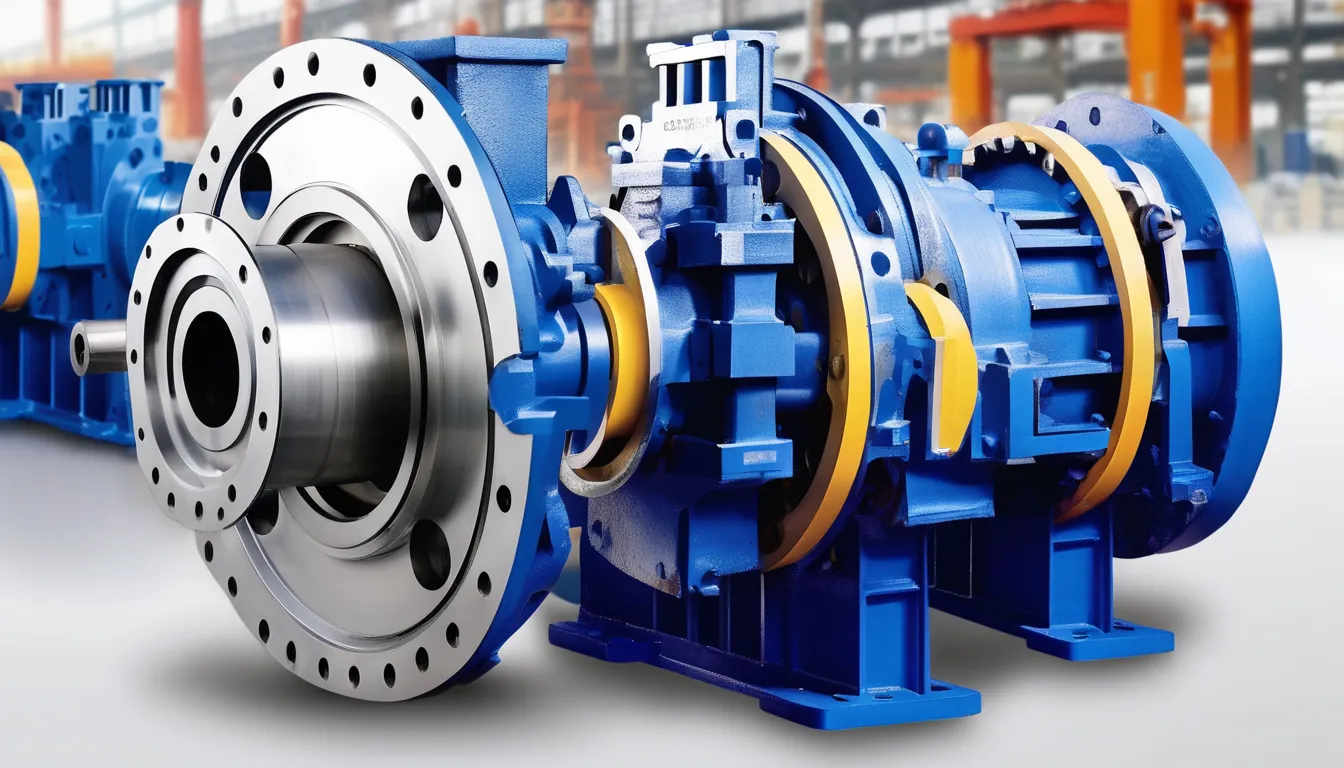

Understanding the gearbox manufacturing landscape is crucial for industries relying on efficient power transmission systems. Gearboxes play a vital role in converting and controlling power from motors to machinery, ensuring optimal performance in various applications. You’ll find gearboxes in everything from automotive systems to wind turbines, highlighting their importance across sectors.

Manufacturing gearboxes involves a series of precise processes, including design, material selection, machining, and assembly. Each step requires careful attention to detail to ensure durability and efficiency. You need to consider factors such as load capacity, gear ratios, and environmental conditions when selecting or designing a gearbox.

Technological advancements have led to innovations in gearbox manufacturing, making processes faster and more efficient. Automation and computer-aided design (CAD) tools allow you to create complex designs that meet specific performance criteria while reducing production time.

Additionally, sustainable manufacturing practices are gaining traction, helping to minimize waste and energy consumption in the production process.

As you navigate the gearbox manufacturing landscape, understanding these elements will help you make informed decisions that enhance productivity and reliability in your operations.

Key Global Players

The Helical Gearbox manufacturing industry is shaped by several key global players who drive innovation and set standards for quality and performance. Companies like Siemens, ABB, and Bosch are at the forefront, leveraging their extensive expertise to create high-performance gear systems that cater to various applications. These industry giants invest heavily in research and development, ensuring their products meet stringent efficiency and durability requirements.

You’ll find that these players often collaborate with other manufacturers and technology firms to enhance their offerings. For instance, they may join forces to develop smart gearbox solutions that integrate seamlessly with automation systems. This collaborative approach not only fosters innovation but also helps them stay ahead of emerging market trends.

In addition to these established companies, regional players like SEW Eurodrive and Nord Drivesystems also make significant contributions. They focus on niche markets, providing tailored solutions to meet specific customer needs. By understanding the unique demands of various industries, these companies position themselves as indispensable partners in the gearbox manufacturing landscape.

Ultimately, these key global players play a crucial role in shaping the future of gearbox technology and ensuring the industry’s continued growth and advancement.

Emerging Technologies in Gearboxes

Emerging technologies are revolutionizing the gearbox manufacturing industry, introducing innovative solutions that enhance efficiency and performance. One significant development is the integration of smart sensors into gearbox systems. These sensors monitor real-time data, providing insights into performance, wear, and potential failures. By leveraging this data, you can optimize maintenance schedules and reduce downtime.

Another exciting advancement is the use of advanced materials, including lightweight composites and high-strength alloys. These materials improve durability while reducing weight, leading to more efficient operation.

Additionally, additive manufacturing, or 3D printing, allows for the creation of complex gearbox components that were previously impossible to manufacture. This technology not only shortens production times but also enables customization to meet specific application needs.

Moreover, digital twin technology is becoming increasingly popular. By creating a virtual replica of your gearbox, you can simulate performance under various conditions, allowing for better design and testing processes.

As these technologies continue to evolve, they promise to redefine the capabilities of gearboxes, making them more efficient, reliable, and adaptable to changing industry demands. Embracing these innovations will position you at the forefront of the gearbox manufacturing landscape.

Regional Market Trends

As innovative technologies reshape gearbox manufacturing, regional market trends are also evolving, driven by unique demands and economic conditions across different areas.

In North America, for instance, you’ll notice a strong push towards automation and robotics, which fuels the need for high-performance gearboxes in various industries, including automotive and aerospace. This region emphasizes energy efficiency and sustainability, impacting design requirements.

In Europe, the trend leans towards advanced materials and lightweight designs, reflecting stringent environmental regulations. Manufacturers here are focusing on developing gearboxes that not only meet performance standards but also reduce carbon footprints.

Meanwhile, Asia-Pacific is witnessing rapid industrialization, which creates a high demand for gearboxes in manufacturing and construction sectors. Countries like China and India are investing heavily in infrastructure, making them pivotal markets for gearbox suppliers.

In Latin America and Africa, the trends are more varied, often influenced by local economic conditions and infrastructure development needs.

Challenges and Opportunities

Navigating the gearbox manufacturing landscape presents both challenges and opportunities that can significantly impact your strategy.

As you delve into this industry, you’ll encounter hurdles like fluctuating raw material costs, stringent regulations, and the need for rapid technological advancements.

However, with these challenges come unique opportunities to innovate and differentiate your products.

Consider the following aspects that can shape your approach:

- Emerging markets: Tapping into regions with growing demand can expand your customer base.

- Sustainability initiatives: Embracing eco-friendly practices can enhance your brand’s reputation and attract conscientious consumers.

- Technological integration: Investing in automation and smart technology can streamline operations and boost efficiency.

- Collaboration: Forming alliances with suppliers and partners can lead to shared resources and innovation.

- Customization: Offering tailored solutions can meet specific customer needs, setting you apart from competitors.

Conclusion

In conclusion, the global gearbox manufacturing landscape is thriving with innovation and sustainability at its core. Major players are pushing boundaries through technology, while emerging trends like smart sensors and additive manufacturing pave the way for enhanced performance. As you navigate regional variations in demand, remember that both challenges and opportunities await. Staying informed and adaptable will empower you to thrive in this dynamic industry, ensuring you’re well-equipped to meet the evolving needs of the market.